Turning environment

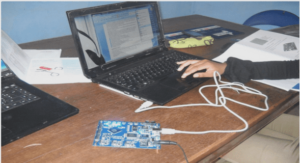

Dry turning is frequently conducted due to the environmental and health regulations and reduction in the turning costs. However, it can produce high cutting temperature. In wet turning, cutting fluids are used during turning to reduce the generated temperature in both workpiece and tool and the friction at the tool-workpiece interface. However, cutting fluids with high flow rates not only are hazardous to the machinist health and the environment but also increase the turning costs. To avoid having all of these problems, another lubrication mode such as minimum quantity lubricant (MQL) is recommended. This method assists to have clean turning and eliminate the serious problems associated with traditional dry and wet turning operations. The most significant advantage of MQL system is that the lubricant with small flow rates is applied directly to the contact area, avoiding the thermal shocking of the cutting tool and increasing the surface integrity and quality. Figure 0.1 displays a turning operation using MQL system.

Machining and surface integrity characteristics Metal turning generates high machining forces and temperatures, which lead to residual stresses. It is recognized that high temperature causes inaccuracies in the dimensions of the component. High machining forces increase the power consumption and cause an excessive deflection of the tool, and as a result, tool breakage. In addition, both high machining temperatures and forces result in large tool wear, and consequently, high surface roughness. Moreover, tensile residual stresses induced by turning processes have harmful influences on the samples due to opening tiny cracks, which subsequently decrease the resistance to fatigue and corrosion (Sadeghifar, 2017). Therefore, the analysis and optimization of machining characteristics including machining temperature and forces and surface integrity characteristics consisting of residual stresses and surface roughness parameters are required.

Finite element method Numerical modeling of machining operations can be traced back to the early seventies when in-house finite element models were developed. With the advent of high-performance advanced computers and the development of new methods to model high strain rate and plastic deformations processes, turning operations can be simulated using the available software packages such as DEFORMTM, Abaqus®, and AdvantEdgeTM to predict machining characteristics and surface integrity accurately. The developed FE models are reliable tools which enable manufacturers to predict machining and surface integrity characteristics while avoid conducting a large number of expensive, time-consuming experimental tests. Surface integrity

In manufacturing processes, the improvement of surface quality is one of the major issues of interest for customers. Surface integrity refers to surface roughness and residual stress, which are used for evaluating the quality of final products. Mostly, fatigue, creep, crack, and corrosion invariably start at the surface of components and affect the quality of the surface. Therefore, it is important to understand residual stresses and their tensile or compressive nature induced by machining processes (Ji et al., 2014). Machining processes affect surface integrity characteristics due to non-uniform changes between the bulk material and the machined surface layers (Touazine et al., 2014). Therefore, it is required to obtain optimal turning parameters to improve surface integrity under various turning environments.

Effects of turning environments and parameters on surface roughness Although the effect of turning parameters on surface roughness was investigated by many researchers, a small number of research works studied and compared surface roughness parameters for different turning environments. Boulahmi (2015) conducted experimental research on the effect of feed rate and tool’s nose radius on surface roughness parameters in turning AA2024-T4, AA6061-T6, and AA7075-T651 for various environments such as dry, MQL and wet. The results showed that MQL turning provided the smallest surface roughness parameters. However, the influences of cutting speed and depth of cut on surface roughness were not studied. Moreover, the optimization of overall surface integrity was not conducted. Sreejith (2008) analyzed the influence of various environmental modes including dry, MQL, and wet, and cutting speed on surface roughness in turning of AA6061. As shown in Figure 2.1, for all the cutting speeds, applying coolant/lubricant improved surface roughness. Furthermore, average surface roughness rose at a larger cutting speed for all the environmental modes. The results also demonstrated that MQL mode was a good alternative to wet mode. However, the effects of high cutting speed, feed rate, and depth of cut on surface roughness were not studied under different turning environments. Moreover, residual stresses were not studied and optimized under different turning parameters and environments.

Regression modeling and optimization of surface integrity characteristics Regression modeling and optimization studies of surface integrity induced by turning processes of metals were investigated by some researchers. Kirby et al. (2006) carried out research on AA6061-T6 to obtain the optimal dry turning parameters including spindle speed, feed rate, depth of cut, and tool nose radius in order to reduce surface finish using a Taguchi’s L9 orthogonal array experimental design approach. The results demonstrated that feed rate and tool nose radius were the most efficient parameters on surface roughness. Horváth and Drégelyi-Kiss (2015) studied the impact of cutting speed, feed rate, depth of cut, and tool’s cutting edge shape on surface roughness of aluminum alloys. CCD, RSM, and multiperformance optimization were used and cutting speed and feed rate were found to be the most influential parameters. Camposeco-Negrete (2015) performed a research work on rough turning of AA6061-T6 in wet environment using CCD and RSM and concluded that feed rate was the most influential parameter for reducing surface roughness. However, the influence of turning environment and parameters on residual stresses was not investigated numerically and experimentally and optimization was not performed.

2D/3D finite element prediction of machining characteristics and residual stresses Since last decades, FE modeling and simulation of machining operations have attracted many researchers’ attention. There are a small number of software including DEFORMTM, Abaqus®, ANSYS, and AdvantEdgeTM for modeling of machining operations using FEM. The developed FE models are reliable tools which enable manufacturers to improve both the productivity (material removal rate, tool life, etc.), part surface integrity (residual stresses, microstructural alterations), and fatigue life and corrosion resistance (Jomaa et al., 2017). To validate the developed FE models, experimental results of machining characteristics and surface integrity should be utilized. In the following, an overview on the latest FE research works on machining characteristics and surface integrity induced by turning processes, with a particular focus on aluminum alloys is provided. Guo et Liu (2002) investigated the effect of cutting parameters on machining characteristics and residual stresses in turning of AISI 1020 using Abaqus® software. The results showed that compressive residual stresses were generated by reducing uncut chip thickness to below a threshold value in the second sequential cutting pass. Yen et al. (2004) analyzed the influence of various tool edge parameters on cutting parameters using simulations of orthogonal cutting of AISI 1020 with DEFORM-2DTM software. They revealed that tool wear was directly dependent on machining temperature, stresses on the tool, and chip velocity.

INTRODUCTION |