Detection de l’Interaction Pastille-Gaine (IPG) et de la fusion à cœur lors d’une

irradiation de type transitoire de puissance dans le reacteur Jules Horowitz

THERMO-PHYSICAL PROPERTIES OF NUCLEAR FUEL MATERIAL AT MELTING ONSET

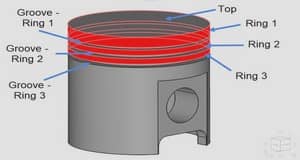

Introduction This part of the work aims at evaluating the theoretical effect of a partial fuel melting on the deformation of a fuel rod. The frame of the study is the same as before: a PWR fuel rod made of UO2 pellets presenting a burn-up of about 30 GWd/tU, so in the critical range for PCI analyses, submitted to a power transient. But in this case the hypothetical power variation leads to very high temperatures in the fuel, the centerline temperature exceeds melting points and the material starts melting. The subject of melting fuel material is not new in the nuclear context. Several studies have been carried out in the past 60 years to define the melting point of the fuel material and to characterize the effect of influencing parameters: fuel composition, stoichiometry and burn-up. The thermal and mechanical implication of molten fuel originating in the case of severe accidents have been largely investigated for safety purpose [All85] [Cam87] [Sil79]. None of these studies takes into account the existence of a molten phase. Recently, the non congruent melting of the fuel material has been studied by Welland [Wel09] for an hyperstoichiometric fuel. All the aforementioned researches considered the case of a defective cladding, where the loss of integrity lead to the reaction of the coolant with the UO2. From the reaction it results a strong oxidation of the fuel material. The first peculiarity of our study is that we assume that the power transient does not induce the loss of integrity of the cladding, so the oxidation reaction doesn’t drive the oxygen redistribution in the system. Secondly, the aforementioned research use the Phase Field model to evaluate the thermal behavior of melting fuel material but there is no available model in the open literature which accounts for the presence of liquid on the mechanical performance of the fuel. Before to introduce the homogenization approach which has permitted the development of the thermal-mechanical model to describe the behavior of the nuclear material undergoing central melting, we need to define the main thermophysical properties of interest in the process which will be used as starting point in chapter 6: the definition of the melting interval, the enthalpy of melting and the characteristic expansion appearing at melting onset. This latter peculiarity has a first order importance in our study has it may be the driver for a signature, measurable behavior.

The melting temperature of UO2

The melting point of UO2 has been the object of various studies in the past 60 years. Its measurement is not a trivial problem as a consequence of the very high temperature to be characterized, the several investigation techniques which have been used and the chemical interaction of the compound with the containment or with the surrounding atmosphere. Figure 4.1 is extracted from the work of Baichi [Bai06]: it presents the historical evolution of experimental data on the measure of the melting temperature of UO2 and highlights the strong data dispersion resulting from the mentioned difficulties. In the early 2000’s, the experts of International Atomic Energy Agency (IAEA) [IAEA05] stated as recommended value for the melting point of stoichiometric UO2 the one proposed by Rand in [Ran78] on the basis of his set of experiments. The recommended temperature is 3120 K ± 30 K. Then, Baichi proposed a critical review of the phase-diagram data of the U-O system in the U-UO2 composition range in order to select the most reliable set of data. The large data dispersion observed is due partly from difficulties in temperature measurements and partly from the chemical behavior of UO2 compound, vaporization and reactivity with the containment or the atmosphere [Bai06]. retained the results obtained by a conventional investigation technique: closed systems, tungsten containers and black body pyrometry conditions [Bai06] ultimately retaining the melting temperature of Latta and Fryxell: 3138 K ± 15 K. Manara in [Man05] reexamined this value proposing to use a modern measurement technique: first, to use a subsecond pulse-heating in order to limit the time at with the investigated material is submitted to the highest temperature and undergoes enhanced reactivity; secondly, avoid the possibility of the sample interaction with the container material by means of container-less techniques, such as levitation. Also, the entire experiment took place under inert gas pressures. This technique guaranteed absence of contamination, suppression of non-congruent evaporation and appearance of influencing phenomena compromising the result. Rejecting the critics from Baichi [Man07], Manara supports a congruent melting temperature for UO2 of 3147 K ± 20 K. For our scope, it is important to highlight that the proposed recommended values are in good agreement with each others once the uncertainties are taken into account. In the following, we consider the melting point for congruent melting proposed by Manara and obtained by a precise modern measurement technique so: Tm = 3147K ± 20K (4.1) During its life in the reactor, irradiated nuclear fuel in no more a pure material and solidliquid phase transition occurs over a melting interval characterized by a lower melting temperature, the “solidus temperature” Tsol, and an upper melting temperature, the “liquidus temperature” Tliq. During the phase transition, fuel material is an heterogeneous composition of the two phases. According to literature [Pop00], the melting interval of the generic nuclear fuel material essentially depends on three parameters: 1. The burn-up BU, expressed in GWd/tU; 2. The ratio oxygen/metallic actinides (O/M) present in the fuel; 3. The fuel composition and especially in the case of MOX fuels, the volume fraction of PuO2, generally identified with the symbol “y”. Those parameters impact the value of the solidus and liquidus temperatures during irradiation. The resulting melting interval is defined by the following equations: Tsol = Tm + ∆Tsol (4.2) Tliq = Tm + ∆Tliq (4.3) We detail in the following how each of those parameters impact the melting process of non stoichiometric uranium dioxide imposing a modification of the solidus or liquidus temperatures.

Effect of the Plutonium content

The volume fraction of plutonium present in the nuclear fuel material after fabrication evolves considerably depending on the fuel material type, from 0% up to 25%. The correlation describing the evolution of melting interval of (U,Pu)O2 material with the composition dates back to experimental measurements carried out in the 70’s by Leon and Bailly [Lyo67] and by Aitken and Evans [Ait68]. The melting temperature of stoichiometric plutonium dioxide has been recently re-evaluated by De Bruycker [DeB10] who highlighted a difference with previous experimental characterizations of approximately 300 K. Previous measurements lead to the determination of the congruent melting point of PuO2 of 2701 K±35 K, Carbajo and al. [Car01], and 2660 K, Gu´eneau and al. [Gue08]. De Bruyker discusses in his article that the previous measurements are affected by an error induced by the conventional measurement technique, which is affected by extensive interaction between the PuO2 samples and the tungsten containment. For the characterization of the melting point of PuO2 the experimental difficulties are the same as for UO2. De Bruycker used the same technological solution proposed by Manara [Man07] and obtained a melting temperature for stoichiometric PuO2 of 3017 K ± 20 K . The available recommended solidus and liquidus curves for a stoichiometric fresh fuel containing a certain volume fraction “y” of plutonium result from detailed analysis [Ada85] of experimental data [Lyo67] [Ait68] obtained previous to De Bruycker study and reported in [Pop00]: ( solidus : ∆T y sol = −388.1y + 30.4y 2 liquidus : ∆T y liq = −655.3y − 336.4y 2 − 99.9y 3 (4.4) where y corresponds to the volume fraction of plutonium. This correlations are thus not completely reliable after the recent results on the melting of congruent plutonium oxide. 4.2.2 Effect of Burn-up The effect of burn-up on the melting interval has been largely investigated in past years by [Ada85] [Yam88] [Kom88] [Kon99] and recently by Carbajo [Car01]. Carbajo critically reviewed the thermophysical properties of UO2 and MOX fuels and reported the comparison figure 4.2 of synthesis for data from these references, taken from [Pop00]. Figure 4.2 – Influence of burn-up on the melting temperature of UO2 and of MOX fuels [Pop00]. From the figure, and in agreement with the final recommendation proposed in [Pop00], he recommended to correct the melting point of the nuclear fuel by decreasing the Tsol. of 0.5 K each GWd/tU: ∆T Bu sol = −0.5BU (4.5)

Effect of oxygen to actinides ratio

According to past studies [Man05] [Kon99] and more recent analysis carried by Gueneau [Gue11], the evolution of Tsol and Tliq as a function of O/M are showed in figure 4.3. The oxygen to actinides ratio O/M of the fuel material is a highly influencing parameter: the deviation from stoichiometry induces a decrease in Tsol and Tliq. Also it progressively increases the difference between the two, thus leading the melting interval to occur over a wider range of temperatures. The non congruent melting of UO2 is presented in figure 4.3: for the hyperstoichiometric region we retained the experimental results obtained by Manara with the container-less measurement technique. In the hypostoichiometric region, the recommended correlations, valid in the range of 1.94 ≤ O/M ≤ 2.00 are the following [Kon99]: ( solidus : ∆T 0/M sol = −103 (2.00 − O/M) liquidus : ∆T 0/M liq = −280(2.00 − O/M) (4.6) We have said in the introduction to this chapter that we consider for our study that melting onset in the fuel material during a very high power transient but this takes place without the failure of the cladding, which preserves its integrity during the whole transient. In a recent paper on ramped Cr-doped fuels, Riglet-Martial [Rig16] showed that the oxygen potential decreases significantly along the pellet radius during the holding period at Ramp 2.1 Temperature [K] O/M ratio Manara, Tsol OAK, Tsol Manara, Tliq OAK, Tliq Figure 4.3 – Evolution of Tsol and Tliq as a function of the oxygen to actinides ratio in the UO2 nuclear fuel. Data from [Man05] for hyperstoichiometric UO2 and from [Kon99] for hypostoichiometric. The deviation from stoichiometry reduces the melting temperature and progressively increases the melting interval Terminal Level (RTL). This phenomenon has been attributed to the oxygen thermodiffusion from the hot pellet center to the cold pellet rim region, a phenomenon which has already been observed in other type of reactors (Sodium Fast Reactor SFR and BWR power ramped fuels). Konarski in [Kon19] implemented in ALCYONE code a model to account for thermochemistry and oxygen transport in the pellet during power ramp test. From the analysis of a power ramp with 12 hours of holding period at RTL=420 W/cm he shows that the oxygen distribution is driven by the thermal gradient and during the first minutes withing the holding period the thermodiffusion induces a decrease of the O/M ratio in the central zone of the pellet. An RTL at 420 W/cm induces a maximum temperature reached in the fuel of about 2000◦C. The higher temperatures reached in the case of melting onset enhances the oxygen redistribution, leading to a stronger decrease of the central stoichiometry. As the scientific community agrees that the maximum temperature is always reached in the pellet center, we can conclude that for our case, we focus on the hypostoichiometric region of the UO2±x system.

I Pellet-Cladding Interaction characterization |