As the size of the world’s population has grown, waste creation has increased rapidly. Plenty of waste materials produced today will remain in the environment for hundreds of years. The creation of non-decaying waste, combined with a growing population of consumers, has resulted in a waste disposal crisis. One possible solution to this coming crisis lies in recycling such waste into valuable products (Reid et al., 2001).

In Quebec, recycling is done through a selective collection. All recyclable materials including carton, paper, glass, and others are collected quickly and in an uncontrolled way from the bins by the selective collection and sent to the sorting centers by truck. In this way the glass breaks in the bin or in the transport and is contaminated (Caillou, 2017). At the sorting center, coarse glass is separated from other materials by manual sorting where possible. Glass pieces that are too small and cannot be sorted manually are mixed together. The combination of several types and colors of glass is called mixed glass. Furthermore, the mixed glass contains of a few numbers of other materials including plastic, paper, and others. The industry of glass recycling remains a challenge in Quebec due to some problems, which are explained more as follows:

(1) New product of glass requires the separation of glass by colors as well as the removal of any debris stuck to the glass (Taha & Nounu, 2008). The high cost of the complicated processes that is required for separating the different colors of mixed glass is an obstacle for producing new glass. Therefore, this contaminated and mixedcolor glass results in a low added-value usage like ending up in the landfills (RECYC-QUÉBEC, 2012).

(2) In 2013 the low economic value of glass eventually led to the closure of the main glass processing plant in Quebec. It was the only company in Quebec with the capacity to process large volumes of clean glass and also to process mixed glass from selective collection (RECYC-QUÉBEC, 2012).

Some research projects are underway to find the new added-value applications for mixed glass. These applications are divided into two categories namely low added-value application and high added-value application. In 2015, 67% of the amount of mixed glass recycled in the province of Quebec was allocated for low added-value applications such as backfill material in landfills (compared to 57% in 2014). However, the proportion of glass sent to recycling companies fell to 25% from 37% in 2014, for high added-value application like glass wool or as an additive to the cement mix used to make concrete (Recyc-Québec, 2014, 2015). According to an estimate by Éco Entreprises Québec, the recycling rate for glass could increase to 54% by 2019, as new glass sorting and cleaning equipment is being tested in some sorting centers in Quebec (Caillou, 2017). Finding an innovative approach of reusing glass can help to increase the high added-value application of mixed glass. Geotechnical engineering applications and especially roadwork applications have become one of the most attractive fields of reusing such materials. However, it is important to notice that the use of such materials should not lead to decrease either the bearing capacity or the life cycle of roads (Rabaiotti & Caprez, 2005). Several research projects concerning the recycling of glass aggregates in pavement materials were carried out at the Pavement and Bituminous Materials Laboratory (LCMB) of the École de Technologie Supérieure (ÉTS). This thesis is devoted to using recycled glass (RG) as a replacement for aggregate in pavement structures, which can be a solution for the problems of glass recycling in Quebec.

The research studies so far by various researchers around the world reveal that, although RG is recognized to have many applications such as drainage and backfill, the limited knowledge concerning the engineering characteristics has slowed down its reuse potential (Wartman et al., 2004a). Furthermore, in the published regulations and specification of the Ministry of Transport, Urban Mobility and Electrification of Transportation of Quebec (MTMDET), there is not any permission of using RG in various roadwork applications as a replacement of natural aggregate. Nevertheless, using some recycled materials in the roadwork such as asphalt or concrete, concrete brick, and clay brick, are authorized by Bureau de normalisation du Québec (BNQ) (BNQ, 2002). Hence, the shortage of knowledge on precise characteristics of RG motivates the author to investigate the geotechnical performance of RG as granular base aggregate and to fill the gap on the geotechnical characteristics. The main objective of this research is to enhance the high-added value usage of RG through studying the advantages and boundaries of using RG in granular materials of the pavement structure, namely base course. The focus of this research is to investigate the hydraulic and mechanical aspects of using RG in base course, which has major roles in the performance of base course structure as discussed in the chapter of literature review.

Introduction to using RG as granular aggregate in base course

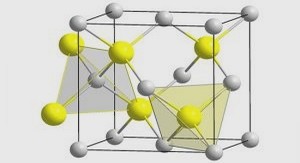

Supercooling of a melted liquid mixture consisting of silicon dioxide, SiO2, and sodium carbonate, Na2CO3, to a rigid condition produces glass. In the mentioned phenomenon the produced material does not crystallize and hold the structure of melted liquid (FHWA, 1998). The common glass contains about 70% SiO2 in which Na2CO3 acts as a fluxing agent in the production process. Other additives are also used in producing glass to obtain specific properties, and different iron compounds are applied as coloring agents (FHWA, 1998). The glass is categorized into various types based on its chemical properties including binary alkali-silicate glass, borosilicate glass, and soda-lime silicate glass (Shayan & Xu, 2004). Window glass and glass bottles are in the subcategory of soda-lime silicate glass, which is composed of 70 to 73 percent of SiO2.

All kinds of glass can be indefinitely recycled because it can retain the similar properties of the reference glass used in the manufacture (Gagné, 2010). However, using RG in manufacturing new glass needs to separate glass by colors. The mixed glass is proposed to be used in other applications including concrete aggregate, fiberglass insulation, road work, or sent to the landfill (Shayan & Xu, 2004). The ever-increasing rate of disposal materials highlights the requirement of recycling more waste materials to reduce the demand for landfills and primary natural resources (Halstead, 1993). Hence, achieving innovative methods of reusing million tons of such materials is a widespread goal (Taha & Nounu, 2008). One of the most practical methods among new ways of reusing waste materials is applying them in roadwork especially in unbound layers of the pavement structure.

Pavement structures include three layers, subgrade, aggregate base/subbase and surfacing layer. The base course is a layer of aggregate that lies below surfacing layers and usually consists of crushed aggregate or recycled material (White et al., 2004). According to Dawson (Dawson, 1995), the important roles of base course aggregate in pavements include the following items:

(1) Protecting subgrade from significant deformation because of traffic loading and against frost and environmental damage

(2) Providing sufficient support for the surface layer

(3) Providing a stable construction platform during pavement surfacing

(4) Providing adequate drainage of moisture that enters in pavement structure

Since the unbound layers of pavement play a principal role in the structural capacity and also the drainage of excess water, investigating both mechanical and hydraulic characteristics of the blends of RG with common unbound aggregate is essential. The following sections of this thesis will focus on the different aspects of using RG in the unbound granular aggregate of base course.

Environmental assessment and physical aspects

The different kind of debris in RG including ceramics, metals, organic and other inorganic materials, cause environmental concerns (Disfani et al., 2012). Various types of debris or contaminants in glass particles as construction materials are recommended to be restricted to 5% (CWC, 1998). The Clean Washington Centre (CWC, 1998) investigated the environmental suitability of RG as construction material. The chemical properties of glass are in appropriate ranges without any problem for construction aggregate users (CWC, 1998). Also, the results of study on leaching tests of glass by Wartman et al. (2004b) showed that there is no hazardous contamination in glass.

Various factors influence the geotechnical characteristics of RG provided by different suppliers (Disfani et al., 2011a). For instance, the processing equipment, procedures of crushing and sieving of different suppliers are not similar. Hence, this difference influences the size gradation and debris level of product which consequently affects the geotechnical characteristics of RG from one supplier to another (Disfani et al., 2011b). Crushed glass particles are generally angular and can contain some flat and elongated particles. The degree of angularity and the quantity of flat and elongated particles depend on the degree of processing and crushing (FHWA, 1998).

INTRODUCTION |