In recent decades, renewable energy sources (RESs) have been the focal point of research among scholars due to their considerable advantages over conventional and fossil fuel-based power plants. Penetration of RESs has been increased substantially in power network in recent decade to provide both consumers and network operators with technical and economic benefits. Technological development of power electronics has also boosted RESs utilization in both transmission and distribution levels of power network (Garcia-Vera, Dufo-Lopez & BernalAgustin, 2019). In recent decade, Canadian government has increased the investment in RES. Currently, Canada is ranked 9th in global wind power generation by producing 2% of global wind power generation and 4% of Canada’s electricity generation (Canadian Wind Energy Association, 2020).

In last decade, electricity usage in urban and rural areas is increased substantially. Considering the electricity history, AC generators gained much more attention based on their abilities over DC generators. Most of the primitive power plants were diesel and steam generators; however, steam and hydro power plants widely added to power networks after a while. The increasing penetration of fossil fuel-based power plants in power grid have raised many environmental concerns which coerces many to see RES as a unique solution for meeting the electricity demand while considerably decreases Co2 emission (Østergaard et al., 2020).

Wind power plants among different RESs have more established technology which made them more popular. Moreover, the energy source is free in these power plants which make them one of the affordable RESs. Besides all the merits that wind power plants have, it should be noted that their presence in power grid creates challenges for grid operators and owners of wind power plants. The intermittent production of power (due to unpredictable nature of wind speed) needs specific control algorithms and considerations that are not taken into account for fossil fuel-based power plants.

Another equally noteworthy challenge in operation of wind power plants is their considerable maintenance expenses. For several years, RESs have been advertised as cutting-edge technologies; however, after passing 20 years from their operation in power network, they cannot be considered as new technologies anymore. More equipment in wind power plants is reaching the end of their life span (Papatzimos et al., 2019). As a result, the O&M costs are increasing substantially in recent years. It has been anticipated that by the end of 2020, over 450 M$ is needed for O&M costs of wind industry in Canada (CanWEA, 2017). Hence, it is highly important for governments and wind power plants owners to keep their competitiveness with fossil fuel-based power plants. Considering high share of O&M costs in total expenses of power plants, finding solutions for reducing O&M costs of wind power plants will be the best way to increase the competitiveness of these power plants.

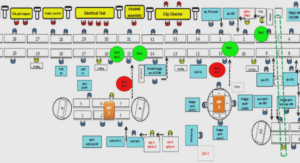

Supervisory Control and Data Acquisition (SCADA) systems

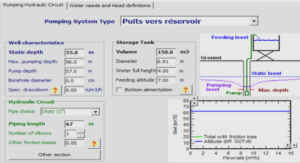

It is worth mentioning that Supervisory Control and Data Acquisition (SCADA) systems are widely used in wind power plants to gather data from equipment and send them to command center for processing and operation. The gathered data by SCADA systems can be used for monitoring the system operation.

The installed sensors, all over the wind power plant, gather data and send them to programmable logic controllers (PLCs) or remote terminal units (RTUs). Data can be sent to PLCs and RTUs manually, as well. PLCs and RTUs convey the gathered data to SCADA system for further actions. In the next step, SCADA systems prepare data for supervisory and operational actions (Setiawan et al., 2018). Usually SCADA systems gather the data from different equipment by 10-mins average. However, SCADA systems are capable of gathering data for higher frequency up to 1 Hz. It is worth mentioning that 10-mins average gathering of data make analyzing system parameters more complex, especially for electrical parameters which usually have faster variations than mechanical ones.

Condition monitoring challenges of wind power plants

Considering the fact that studying horizon (which can be over 10 years) is much bigger than the gathering sample rate (in our case it is 10-mins average), the gathered data will be enormous over the years and as a result, their analysis will be a time-consuming process. The raw data which are gathered by SCADA systems provide the operators with several challenges that should be considered to guarantee proper operational analysis of wind power plants. These challenges can be explained as follows:

• Many of the gathered data may be out of rational operational boundaries. These data can affect proper condition monitoring analysis and moreover, the time required for analysis will be increased significantly. Hence, the raw data should be pre-processed based on the elimination these data (Yang & Shen, 2020).

• Any failure in measurement systems can affect the gathered data. It is highly important to know that the data have been gathered and processed under healthy operation of sensors, PLCs, and RTUs. By knowing the failure report of measurement devices, the faulty data can be deleted from our dataset (Jiang & Srivastava, 2020).

• Condition monitoring analysis is significantly related to the system operation point. Considering the fact that operation point of wind power plants is more variable than fossil fuel-based power plants (due to their dependence on wind speed), it can be deduced that condition monitoring in wind power plants are more complicated.

• The wind power plants experience shut-down periods due to different reasons such as grid operators command, curtailment, high wind speed and etc. The shut-down periods produce blank data in the database which affect the continuity of condition monitoring analysis.

• Another challenge in analyzing SCADA data for wind power plants is mutual interactions between mechanical and electrical parameters. This correlation fails any successful individual investigation for electrical or mechanical data analysis. Hence, any specific parameter monitoring in these systems needs more complicated control algorithms to consider the correlation between mechanical and electrical parameters (Moeini et al., 2019).

• The other challenge for condition monitoring in wind power plants is the geographical position of turbines. It is very important to consider the turbines’ location in the condition monitoring, because the wind speed, shading effects, ambient temperature, altitude, and etc. are several parameters that related to the geographical position of turbines which affect the generated power (Aziz et al., 2019), (Shen et al., 2019), (Patrizi, Ciani, Guidi & Bartolini, 2019).

INTRODUCTION |