Transpiration Velocities Based Sheet Cavitation Model

Sheet cavitation is known to affect the hydrodynamic performances of propellers. It also produces severe pressure fluctuation. Since many ships operate and will increasingly operate in heavily loaded conditions, there is a real need for cavitating propeller simulations in the unsteady-state operating mode. It coincides with the arising of complex viscous two-phase flow simulation capability. The VIRTUE program (Salvatore et al., 2009a) involves several of these viscous two-phase flow simulations around a propeller. Although some convincing results are obtained, the required computing resources are still considered substantial. Furthermore, the use of a viscous two-phase flow solver still requires a cavitation model with some degrees of assumption and simplification. The full understanding of cavitation and its simulation would require a model at the molecular scale. In order to model sheet cavitation, some understanding of this phenomenon is required. One important point of the phenomenon is how the cavity develops on lifting bodies with a round leading edge. Unlike downstream sharp-corner bodies, the mechanism is arguable. Franc (1986), argues based on experimental observations that the leading-edge sheet cavitation requires a laminarboundary-layer separation and that the cavity develops downstream of the laminar-boundary-layer separation point. This mechanism is widely accepted and used as the cavity detachment criterion for many sheet cavitation simulations, see for instance: Brianc¸on-Marjolet and Merle (1999), Salvatore and Esposito (2001), Brewer and Kinnas (1997). Nevertheless, Farhat et al. (2002) demonstrate that sheet cavitation can occur with another mechanism. According to the experimental results obtained at the “Laboratoire de Machines Hy drauliques, Ecole Polytechnique Fed´ erale de Lausanne”, the sheet cavitation phenomenon has ´ been observed without any sign of laminar-boundary-layer separation. This observation might support the Brillouin-Villat criterion or in other words the smooth detachment criterion. This criterion, which consists in choosing the point which guarantees the curvature continuity while respecting the slippery condition and the steam pressure condition, is used by most simulations, for example: Kinnas and Fine (1993), Lee and Kinnas (2004). Once sheet cavitation has developed, some assumptions for pressure distribution must be made in order to compute the hydrodynamic forces. Most, if not all models, assume that, as in the boundary layer, the pressure does not vary between the blade surface and the outer bound of the cavity. In other words, the pressure in the cavity is assumed to be equal to the homogeneity of the vapor pressure. As long as the sheet cavitation is partial, the effects on hydrodynamic coefficients are expected to be moderate. Carlton (2007) mentions the early work of Balhan (1951) where it is shown in Figure 1 that the lift coefficients CL and the drag coefficients CD of Karm´ an- ´ Trefftz profiles vary in function of the cavitation number σV . When the cavitation number σV decreases, the lift coefficient first increases slightly. And then it collapses when the cavitation number is such that the cavity does not close on the foil surface. It is generally admitted that the lift coefficient increases in presence of partial sheet cavitation and decreases abruptly when supercavitation occurs.

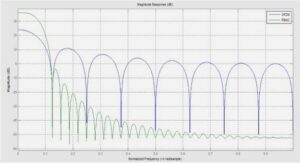

Presentation of cavitation model As mentioned in the introduction, the sheet cavitation model has been developed for direct potential flow codes in which the source strength distribution is imposed directly by slippery condition and the dipole strength distribution is the unknown to be determined. The model uses the transpiration velocities technique in order to take into account the effect of partial sheet cavitation. These transpiration velocities v ∗ are equivalent to the additional source strengths which are simply added to the part of the surface carrying the cavity. Therefore, the implementation of the cavitation model in the potential flow codes is quite simple since it only requires the modification of the source strengths on the body surface where the cavity is, as shown in Equation 1. The problem is then the determination of this additional source strength distribution needed to properly simulate the cavity. σ = U~∞ · ~n + v ∗ on the cavity planform (1) The core of the model is the function used to determine these transpiration velocities v ∗ distribution. We propose that a relationship exists between the cavity geometry and the pressure distribution in subcavitating conditions Psub. Equation 2 describes the proposed relationship.The general computation scheme is described as follows: • Starting from the stagnation point and following the streamline, when the pressure in subcavitating conditions is greater than the vapor pressure (Psub > PV ), the transpiration velocity is set to zero (v ∗ = 0) since the cavity thickness cannot have a negative value (tc ≥ 0). • The cavity starts where the subcavitating pressure crosses the vapor pressure threshold (Psub = PV ). This corresponds to the Brillouin-Villat criterion or the smooth detachment criterion. • Subsequently, the transpiration velocity v ∗ as well as the cavity thickness tc is calculated by using Equations 2 and 3. • The cavity is closed when the cavity thickness returns to zero (tc = 0). • After the cavity closure point, the transpiration velocity is set to zero (v ∗ = 0) once again. Of course, this is due to the fact that the cavity thickness cannot be negative. In this way, the cavity length only depends on the pressure distribution in subcavitating conditions and on the vapor pressure. Neither an additional cavity closure model nor empirical parameters are required. The adaptive factor k which intervenes in the model (Equation 2 or 4) is determined iteratively. Having observed the linear effect of the factor k on the resulting pressure distribution, the iterative procedure used is based on the secant method. The criterion is to obtain the vapor pressure at the maximum cavitation thickness location. Examples of the resulting pressure distribution during an iterative procedure are shown in Figure 2.

Implementation within a 2D steady potential flow code with boundary layer effect The 2D potential flow code with boundary layer simulation was developed in the study presented in Leroux (2003) and Leroux et al. (2003). This 2D potential flow code takes into account the confinement effect by using the images theory. Furthermore, it uses the transpiration velocities to simulate the boundary layer which is computed using an integral boundary layer representation code. As already presented above, these transpiration velocities are also used to represent the sheet cavitation. Nevertheless, it remains to be decided how the boundary layer on the sheet cavitation should be modeled. Literature review on the subject shows some disagreement among experimental observations (Dupont and Avellan, 1991; Brewer and Kinnas, 1997); instead of adding a level of complexity with a sub-model, it is decided to inhibit the boundary layer model where the sheet cavitation is present. The boundary layer is modeled normally from the stagnation point to the trailing edge on the pressure side. On the cavitating suction side, the computation procedure is presented as follows: • The transpiration velocities representing the laminar boundary layer are present from the stagnation point to the sheet cavitation inception point. • From the cavity detachment point to its closure point, the transpiration velocities representing the boundary layer are set to zero. Hence, the boundary layer is considered to have a constant thickness. • Once the sheet cavitation has closed itself, the boundary layer computation is resumed in the turbulent mode with its present thickness. This “boundary layer – sheet cavitation” coupling diagram is presented in Figure 3. The method could be improved but it is always preferable to choose the simplest solution. Furthermore, the current procedure allows to model both the boundary layer and the sheet cavitation in the same simulation.

2.2 Implementation within a 3D unsteady potential flow code The 3D unsteady potential flow code used for all the 3D simulations in this paper is part of what Hoeijmakers refers to as the second generation potential flow codes in his exhaustive presentation of the different existing potential flow codes in Hoeijmakers (1992). The code uses a Dirichlet condition to force the inner body potential function. The inner and outer body flow models are connected at the frontier, the body surface. The wet surfaces are discretized into quadrilateral panels carrying constant distributions of sources and dipoles. The downstream wakes of lifting bodies, propeller blades or foils are modeled by a sheet of quadrilateral panels carrying constant dipoles distributions. The wake is generated in a Lagrangian manner allowing for unsteady simulations. Since the cavitation model is defined on a streamline, an assumption is needed to implement the model within the 3D potential flow code. It is assumed that the perturbation velocities are small compared to the upstream velocities. This assumption allows the implementation of the cavitation model in each band (section) of the lifting bodies, propeller blades or foils. Furthermore, it is decided that the adaptive factor k has a different value in each band. The adaptive factor k in each band is determined independently from the factor k in the other bands with a secant method as in the 2D case. This way, the sheet cavitation model is treated somehow like a strip method. However, the determination of the dipole distribution to satisfy the Kutta-Joukowski condition is carried out in a 3D manner. The relaxation method used imposed that the change of the factor k in each band is forced to not exceed 5% of the value in the previous iteration as shown in Equation 5. if kit+1 > 1.05 kit then kit+1 = 1.05 kit if kit+1 < 0.95 kit then kit+1 = 0.95 kit (5) Moreover, for the reason of unsteady-state flow simulations, another assumption is required. Forced by the principle of the model, it is needed to assume that the vapor inertia due to the phase change is negligible compared to the pressure fluctuation in subcavitating conditions. Hence, the cavity can adapt immediately to the surrounding pressure distribution and does not depend on the previous time-step cavity shape.

Validation of cavitation model

In this section, the first stage of validation is presented. The cavitation model is validated by comparing its numerical results with the experimental data and other numerical results available in literature. There are two cases presented here: the comparison with measured pressure coefficients on a 2D hydrofoil and the comparison with measured cavity lengths on a 3D hydrofoil.

3.1 Comparison with measured pressure coefficients over a 2D hydrofoil

Experimental trials of a cavitating 2D hydrofoil have been performed in a cavitation tunnel and presented in Leroux (2003) and Leroux et al. (2003). The conditions of the trials are sufficiently documented to be used for a validation of the sheet cavitation model. These trials have already been used for this purpose by several model developers; see for instance Leroux et al. (2005). In this study, the measured pressure coefficients obtained for various cavity lengths are used to validate the present cavitation model. In summary, the instrumented hydrofoil with pressure taps is a NACA66(mod)–312 a=0.8 (relative maximum thickness 12% and maximum camber 2%) with a chord length of 150 mm. The hydrofoil is installed in the square test section (192mm×192mm) of the IRENav-EA3634 cavitation tunnel. Both the flow velocity and the pressure are controlled in the cavitation tunnel. The angle of attack of the hydrofoil is set to 6 ◦ and the Reynolds number Re is about 7.5 × 105 . For a quantitative comparison with the experimental results as described in Leroux (2003), the correction procedure for the inlet velocity in the trials has to be rigorously applied to all pressure coefficients and all cavitation numbers. Furthermore, Leroux (2003) also shows that for this study the effects of confinement and boundary layer are not negligible and should therefore be taken into account.