Télécharger le fichier original (Mémoire de fin d’études)

Context

Polypropylene-based materials are widespread in the automotive industry due to their low cost, chemical resistance, good mechanical properties or even recyclability. Thermo-Plastic Olefins (TPO), which refer to blend of polypropylene with ethylene-propylene rubber (EPR) in order to confer scratch and impact resistance, are particularly used in exterior parts such as bumpers and side protectors. Nowadays, these TPO are commonly synthesized by multistage polymerization, which improves compatibility of phases and thereby enhances their mechanical properties as well as their processability (high Melt Flow Rate). They still account for more than 50% in volume and 25% in value of the polymer amount in a car and their use, including in thermoplastic composites, is intended to be increasingly popular in the perspective of lightening vehicles. Indeed, this is an important leverage in order to satisfy the requirements of the European regulation (N° 443/2009) in terms of CO2 emissions for light-duty vehicles (95 g CO2/km before 2020).

The main drawback of polypropylene is its degradation under the combined effects of oxygen with temperature (thermal oxidation) or UV-light (photooxidation). Indeed, most of the alteration of both mechanical and aspect properties (loss of gloss, whitening, chalking…) has been ascribed to the occurrence of macromolecular chain scissions and the subsequent formation of a lattice of micro-cracks [1-3]. Today, it is widely accepted, in the scientific community of polymer degradation, that the relevant scale to investigate these phenomena is the chemistry of oxidation. The subsequent alteration of upper-scale properties can theoretically be calculated provided that the structure-properties relationships have been identified. The issue is thus to ensure the durability of materials specifications, particularly in terms of perceived quality, and thereby focusing on aspect properties.

In a demanding context of time-to-market reduction, the challenge for R&D departments is to shorten validation periods while aging tests in real conditions are very time-consuming. Different strategies can be envisaged:

(i) The choice of materials (and their suppliers) can be restricted to a shortened list which has passed validations test upstream, at the expense of the innovation responsiveness.

(ii) The aging tests can be accelerated by applying harsher conditions in terms of UV-light intensity, temperature or frequency of rainfalls for instance. However, these accelerated test methods must be representative of the real-use conditions in order to be reliable: in other words, the relative importance of the different phenomena under competition must be kept unchanged. This point has been particularly emphasized in the so-called mechanistic approach, supported by Lemaire, Gardette and coworkers (Clermont-Ferrand), which consists in ensuring that the mechanisms of degradation are similar in natural (outdoor) and accelerated exposure conditions [4, 5].

(iii) The impact of the various factors (environmental stresses and materials constituents) on polymer aging can be capitalized (feedback). This can be done by “statistical modeling”: lifetimes relative to a given property are interpolated generally using polynomials. The other possibility is to simulate the chemical changes depending upon the aging factors, namely the composition of the material and the harshness of the environmental factors. This can be done by applying an approach of kinetic modeling. The main advantage of this latter approach is its heuristic feature thereby enabling extrapolation of the model to longer durations or softer aging conditions.

To date, there is still a long way to go before obtaining a tool viable for lifetime prediction of commercial materials in real-use conditions. Many physicochemical phenomena are involved as a consequence of the complex industrial formulations containing stabilizers [6] –additives conferring the long term stability- fillers or pigments [3, 7, 8]. Modeling their effects on aging requires understanding the impact of each environmental factor and material constituent, their possible interactions depending on the initial state (amount of structural defaults [6, 9] and thermal history given by the processing conditions [10]). The scope of this thesis has thus been restricted to the case of the unstabilized TPO, free of any additive or filler.

This study is the result of the collaboration between the laboratory of Processing and Engineering in Mechanics and Materials (PIMM, Arts et Metiers ParisTech, CNRS) and the automotive company Renault in the framework of the project POLAR (POLymer Aspect Reliability).

Objectives

The aim of this thesis thus consists in designing a kinetic model for the photothermal oxidation of isotactic polypropylene and its impact copolymers. This approach has been initiated for two decades in the PIMM laboratory by investigating alternately the effect of temperature [11], UV-light [12] or oxygen partial pressure [13] on the oxidation kinetics of polypropylene and its subsequent properties changes [14]. An important stake will be to upgrade the numerical tool established for thermal oxidation to the case of the photothermal oxidation. Besides a tool for lifetime prediction, numerical simulation must be above all considered as a research tool, a way to put to the test various mechanistic assumptions and thus to elucidate the impact of the exposure conditions on the oxidation kinetics. A particular attention will be also dedicated to the aging methodology and their reliability.

Structure of the dissertation

The literature overview, given in chapter aims at making an inventory of the involved mechanisms in photothermal oxidation, focusing particularly on additional mechanisms induced by the UV-light mainly initiation processes. A particular attention will be dedicated to the mechanistic considerations which lay the foundations of the kinetic modeling approach. Chapter 2, will focus on methodological aspects in relation with the sources of errors, both experimental and numerical, which is necessary in order to apprehend the reliability of the proposed model.

The first results chapter will be dedicated to thermal oxidation which constitutes the core and a subset of the photothermal model since temperature is an intensive quantity in any system. However, the thermal model has been established in very different conditions from solid [8, 11, 14, 15] to molten states [16], thereby resulting in slight predictive discrepencies depending upon the mechanistic and kinetic assumptions. Thus, the challenge will consist in unifying the different proposals of thermal model and checks its validity whatever the temperature, oxygen pressure or material thickness. In chapter 3, the emissions of volatile organic compounds (VOCs) during the thermal oxidation of polypropylene at 140°C will be monitored in real-time by using Fourier transform ion cyclotron resonance mass spectrometry. This original method enables to investigate the impact of VOCs emissions on the mechanisms of polypropylene thermal oxidation and its kinetic modeling. Following these complementary mechanistic considerations, chapter 4 and 5 will be dedicated to establishing a unique kinetic model for thermal oxidation, mainly focusing on the impact of oxygen transport properties. In chapter 4, the oxygen solubility will be shown to be a critical parameter to report the whole diversity of iPP oxidation behaviors, in close connection with the effect of oxygen partial

Table des matières

CONTENTS

GENERAL INTRODUCTION

1. CONTEXT

2. OBJECTIVES

3. STRUCTURE OF THE DISSERTATION

4. INTRODUCTION GENERALE [TRANSLATION IN FRENCH]

CHAPTER I. OVERVIEW OF THE LITERATURE

RESUME [SUMMARY IN FRENCH]

INTRODUCTION

1. MACROMOLECULAR MECHANISMS OF OXIDATION

1.1. Initiation processes: multiplicity and predominance of species

1.2. Propagation and multiplicity of reactive sites

1.3. Termination

2. KINETIC TREATMENT

2.1. Formalism of the closed- loop scheme

2.2. Extension to the photothermal oxidation case

1.1. The heterogeneity of oxidation: a scale issue.

CONCLUSION: GENERAL STRATEGY AND RESEARCH SURVEY

CHAPTER II. MATERIALS AND METHODS- METHODOLOGICAL ASPECTS

RESUME [SUMMARY IN FRENCH]

1. INTRODUCTION

2. METROLOGY: GENERAL CONSIDERATIONS IN AGING EXPERIMENTS

2.1. The criteria for oxidation monitoring

2.2. Estimation of uncertainties and “error” bars

3. MATERIAL PREPARATION AND CHARACTERIZATION

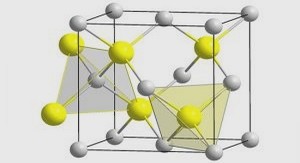

3.1. Isotactic polypropylene morphological features

3.2. Procedure of purification in Soxhlet

4. CONTROL OF THE EXPOSURE CONDITIONS IN PHOTOTHERMAL AGING

4.1. Design of the tests matrix: an incremental approach

4.2. Specification of irradiation devices

4.4. Control of the temperature: difficulty in monitoring fast aging kinetics

5. ERRORS IN NUMERICAL SIMULATIONS

PART 1/ THERMAL OXIDATION.

THERMOOXYDATION DU POLYPROPYLENE [SUMMARY IN FRENCH]

1. UNIVERSALITE ET AUTO-COHERENCE DU MODELE

1.1. Dépendance à la pression partielle en O2 (échelle locale)

1.2. Modélisation multi-échelles du système

1.3. Simulation de la variabilité des comportements

1.4. Domaine de validité et pouvoir prédictif

2. ALTERATION DES PROPRIETES AU COURS DU VIEILLISSEMENT ET CONSEQUENCES EN MODELISATION

CHAPTER III. REAL-TIME QUANTITATIVE ANALYSIS OF VOLATILE PRODUCTS GENERATED DURING SOLID-STATE POLYPROPYLENE THERMAL OXIDATION

ABSTRACT

1. INTRODUCTION

2. EXPERIMENTAL SECTION

2.1. Materials

2.2. Analysis

2.3. PTR-FTICR: apparatus & methods

3. RESULTS AND DISCUSSION

3.1. Real-time analysis: identification and quantification of VOCs

3.2. Effects of oxygen pressure

3.3. Mechanistic discussion

4. CONCLUSION

CHAPTER IV. ON THE IMPACT OF OXYGEN TRANSPORT PROPERTIES ON POLYPROPYLENE THERMAL OXIDATION. PART I: EFFECT OF OXYGEN SOLUBILITY

ABSTRACT

1. INTRODUCTION

2. EXPERIMENTAL PART..

2.1. Materials

2.2. Thermal aging conditions and FTIR aging monitoring

2.3. Characterization by complementary destructive analyses

2.4. Molecular weight measurements

2.5. Oxygen permeability

3. THEORY OF FORMAL KINETIC MODELING

3.1. Closed-Loop Mechanistic Scheme

3.2. Strategy for the optimization procedure

4. MODEL CALIBRATION WITH IPP1 IN OXYGEN DEFAULT

4.1. Determination of the oxygen transport properties

4.2. Modeling the changes in primary oxidation products

4.3. Modeling the build-up of secondary oxidation products

4.4. Modeling the changes in average molecular masses

5. DISCUSSION: TOWARDS A “UNIVERSAL” KINETIC MODEL

5.1. Common sources of variability in connection with initiation processes

5.2. Introduction of a variability on the coefficient of oxygen solubility

6. CONCLUSION

7. APPENDICES

7.1. Model equations, numerical computation and resolution

7.2. Analytical relationships for describing the oxygen pressure dependence of oxidation behavior

CHAPTER V. ON THE IMPACT OF OXYGEN TRANSPORT PROPERTIES ON THE KINETIC MODELING OF POLYPROPYLENE THERMAL OXIDATION. PART II: EFFECT OF OXYGEN DIFFUSIVITY

ABSTRACT

1. INTRODUCTION

2. EXPERIMENTAL PART

2.1. Materials

2.2. Thermal aging and physico-chemical characterization

2.3. Oxygen permeability tests

3. KINETIC MODELING

4. RESULTS AND DISCUSSION

4.1. Variability of oxygen transport properties

4.2. Simulation of oxidation profiles – Impact of oxidation on oxygen transport properties.

4.3. Impact of iPP thermal oxidation on the kinetic modeling

5. CONCLUSION

PART 2/ PHOTOTHERMAL OXIDATION

PHOTOOXYDATION DU POLYPROPYLÈNE [SUMMARY IN FRENCH]

1. INTRODUCTION

2. INTRODUCTION DE L’EFFET DE LA LUMIERE

2.1. Modèle analytique

2.2. Modèle numérique

3. LE CAS DE LA PIECE EPAISSE : COUPLAGE AVEC LE TRANSPORT DES REACTIFS MIGRANTS

CHAPTER VI. INFLUENCE OF TEMPERATURE, UV-LIGHT WAVELENGTH AND INTENSITY ON POLYPROPYLENE PHOTOTHERMAL OXIDATION

ABSTRACT

1. INTRODUCTION

2. EXPERIMENTAL PART

2.1. Materials

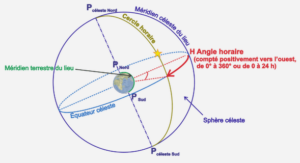

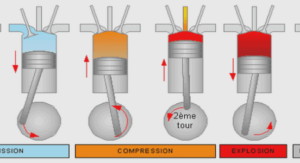

2.2. Light and/or thermal exposure

2.3. Spectrophotometry measurements

3. RESULTS AND DISCUSSION

3.1. Impact of exposure conditions on lifetime

3.2. Cross sections of photosensitive species and calculation of the overlap function

3.3. Interpretation according to an empirical Schwarzschild’s law

3.4. Interpretation using a semi-empirical kinetic approach.

4. CONCLUSION

5. APPENDIX A: THERMAL AGING RESULTS

CHAPTER VII. A GENERAL KINETIC MODEL FOR THE PHOTOTHERMAL OXIDATION OF POLYPROPYLENE

ABSTRACT

1. INTRODUCTION

2. EXPERIMENTAL PART

2.1. Materials

2.2. Photothermal aging

2.3. FTIR analyses

2.4. Hydroperoxides titration

2.5. Molecular weight measurement

2.6. Crystallinity ratios measurement

3. THEORY

3.1. Multi-Closed-Loop Mechanistic Scheme (MCLMS)

3.2. Kinetics in photochemistry

3.3. Model equations

4. EXPERIMENTAL RESULTS

4.1. Photothermal oxidation results

4.2. Comparison with pure thermal oxidation

4.3. Data scattering

5. KINETIC MODELING AND DISCUSSION

5.1. Optimization procedure – Numerical simulations and determination of unknown parameters

5.2. Relative predominance of initiating species

5.3. Validity of the kinetic model

6. CONCLUSION

7. APPENDICES

7.1. Quantum yields from the literature

7.2. Spectral distributions of quantum yields

CHAPTER VIII. CHALLENGES IN THE NUMERICAL SIMULATION OF PHOTODEGRADATION PROFILES

ABSTRACT

1. INTRODUCTION

2. MODEL THEORY AND NUMERICAL RESOLUTION

2.1. Mechanistic scheme

2.2. Photochemical kinetics

2.3. Screening effect

2.4. Formalizing the problem

3. EXPERIMENTAL PART

3.1. Materials

3.2. Photothermal aging

3.3. Oxidation profiles

3.4. Measurements of opacity and reflectance

4. RESULTS AND DISCUSSION

4.1. Potentialities of the improved numerical tool for simulating photothermal oxidation profiles.

4.2. Implementation for simulating experimental data

5. CONCLUSION

CHAPTER IX. GENERAL DISCUSSION

1. INTRODUCTION

2. ADVANCES IN THE KINETIC MODELING OF PHOTOTHERMAL OXIDATION

2.1. Towards a universal model for the thermal oxidation of iPP

2.2. Validity of the CLMS in photothermal oxidation

2.3. Attempts for extending the validity range of the photothermal oxidation model

3. LIMITATIONS OF THE KINETIC MODELING APPROACH

3.1. Implication of simplifying assumptions in formal and homogeneous kinetics

3.2. A complex multiphysical problem: insight from the case of thick specimens

3.3. Expectations from kinetic modeling

4. TOWARDS A KINETIC MODEL FOR PREDICTING THE LIFETIME OF TPO BLENDS

4.1. Describing the thermal oxidation of multiphase materials

4.2. Light attenuation issues in photothermal oxidation of TPO blends

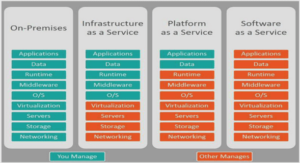

5. DESIGNING AN UPGRADABLE TOOL FOR COMPLEX FORMULATIONS

5.1. Extension to complex formulations

5.2. Risks and challenges in numerical simulation of aging

5.3. Numerical issues

6. APPENDIX: A GENERAL FRAMEWORK FOR THE KINETIC TREATMENT OF PHOTOSENSITIZATION REACTIONS

GENERAL CONCLUSIONS

1. PHOTOTHERMAL OXIDATION MODEL

2. VALIDITY RANGE

3. IMPLICATIONS FOR INDUSTRIAL USE

4. NUMERICAL ISSUES

5. TRANSVERSE THEORETICAL DEVELOPMENTS

6. CONCLUSION GÉNÉRALE [TRANSLATION IN FRENCH]

FIGURES AND TABLES CAPTIONS